Idizayini ye-Optical inezinhlobonhlobo zezinhlelo zokusebenza emkhakheni we-semiconductor. Emshinini we-photolithography, isistimu ye-optical inesibopho sokugxilisa i-beam yokukhanya ekhishwa umthombo wokukhanya futhi iwuveze ku-silicon wafer ukuze kuvezwe iphethini yesekethe. Ngakho-ke, ukuklama nokusebenza kahle kwezingxenye ze-optical ohlelweni lwe-photolithography kuyindlela ebalulekile yokuthuthukisa ukusebenza komshini we-photolithography. Okulandelayo ezinye zezingxenye ze-optical ezisetshenziswa emishinini ye-photolithography:

Inhloso yokuqagela

01 Inhloso yokuqagela iyingxenye ebalulekile yokubona emshinini we-lithography, ngokuvamile ehlanganisa uchungechunge lwamalensi ahlanganisa amalensi aqondile, amalensi ayi-concave, namaprism.

02 Umsebenzi wayo ukuncipha iphethini yesifunda kumaski bese uyigxilisa ku-wafer egcotshwe nge-photoresist.

03 Ukunemba nokusebenza kwenhloso yokuqagela kunomthelela omkhulu ekuxazululeni nasekucabangeni ikhwalithi yomshini we-lithography.

Isibuko

01 Izibukoasetshenziselwa ukuguqula indlela yokukhanya futhi ayiqondise endaweni efanele.

02 Emishinini ye-EUV lithography, izibuko zibaluleke kakhulu ngoba ukukhanya kwe-EUV kudonsa kalula ngezinto, ngakho-ke izibuko ezinokukhanya okuphezulu kufanele zisetshenziswe.

03 Ukunemba kwendawo kanye nokuzinza kwesibonisi nakho kunomthelela omkhulu ekusebenzeni komshini we-lithography.

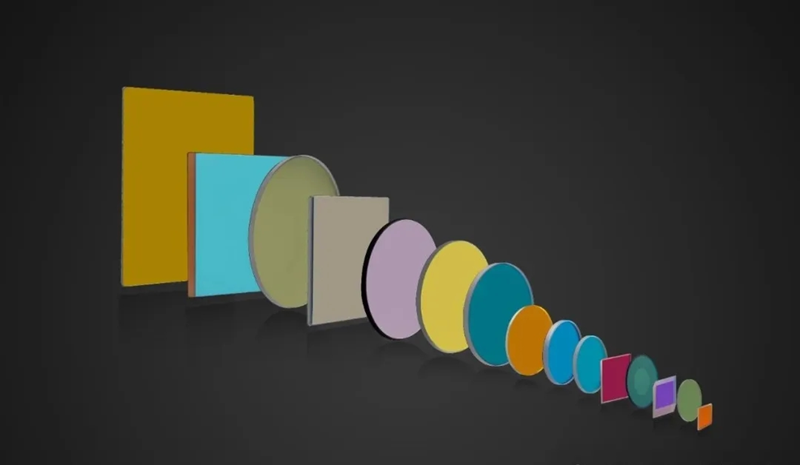

Izihlungi

01 Izihlungi zisetshenziselwa ukususa ubude beza obungafuneki bokukhanya, ukuthuthukisa ukunemba kanye nekhwalithi yenqubo ye-photolithography.

02 Ngokukhetha isihlungi esifanele, kungaqinisekiswa ukuthi ukukhanya kuphela kwe-wavelength ethile kungena emshinini we-lithography, ngaleyo ndlela kuthuthukiswe ukunemba nokuzinza kwenqubo ye-lithography.

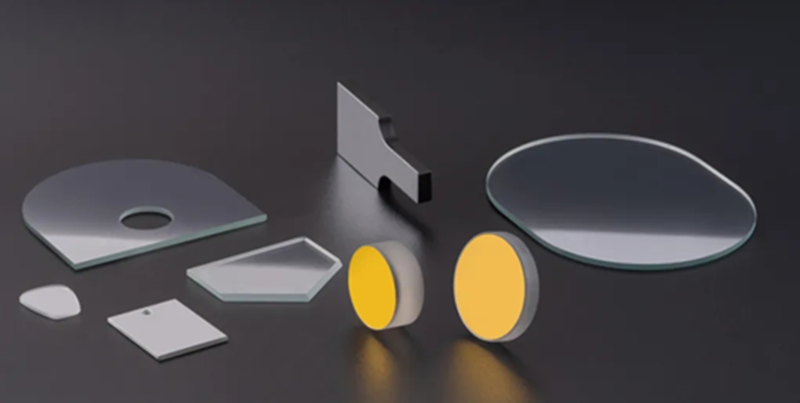

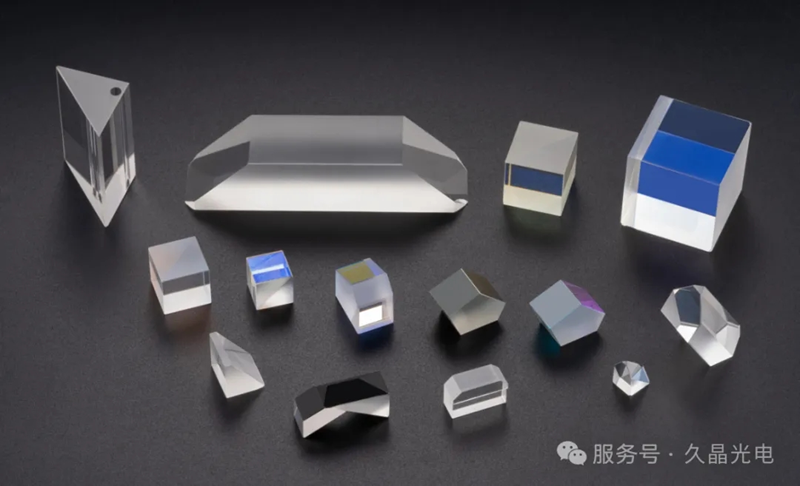

Ama-Prism nezinye izingxenye

Ngaphezu kwalokho, umshini we-lithography ungase futhi usebenzise ezinye izingxenye ze-optical ezisizayo, njengama-prism, ama-polarizers, njll., ukuze uhlangabezane nezidingo ezithile ze-lithography. Ukukhethwa, ukuklama kanye nokukhiqizwa kwalezi zingxenye ze-optical kumele kulandele ngokuqinile izindinganiso ezifanele zobuchwepheshe kanye nezidingo zokuqinisekisa ukunemba okuphezulu nokusebenza kahle komshini we-lithography.

Kafushane, ukusetshenziswa kwezingxenye ze-optical emkhakheni wemishini ye-lithography kuhloswe ukuthuthukisa ukusebenza kahle nokukhiqiza kwemishini ye-lithography, ngaleyo ndlela kusekelwe ukuthuthukiswa kwemboni yokukhiqiza i-microelectronics. Ngokuthuthuka okuqhubekayo kobuchwepheshe be-lithography, ukwenziwa kahle kanye nokuqanjwa kabusha kwezingxenye ze-optical kuzohlinzeka ngamandla amakhulu okwenziwa kwama-chips esizukulwane esilandelayo.

Ukuze uthole imininingwane eyengeziwe nezeluleko zochwepheshe, vakashela iwebhusayithi yethu kokuthihttps://www.jiujonoptics.com/ukuze ufunde kabanzi mayelana nemikhiqizo yethu nezixazululo.

Isikhathi sokuthumela: Jan-02-2025